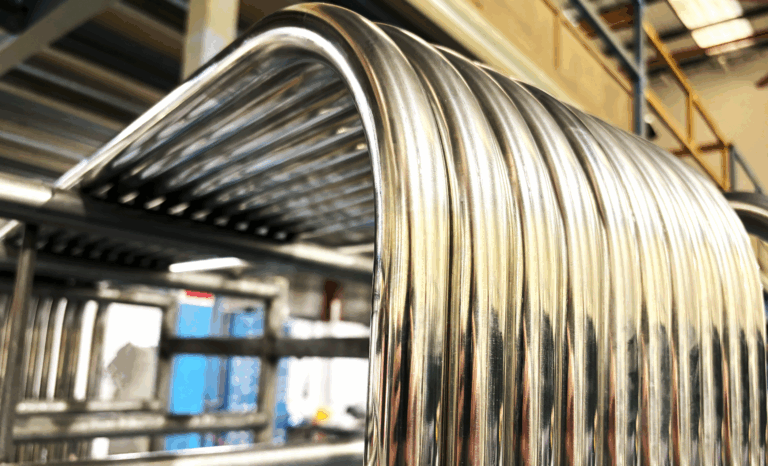

Stainless Steel Polishing

Quality in-house stainless steel polishing for flawless finishes

Stainless Steel Polishing - Achieving the Perfect Finish

Stainless steel polishing is a popular material and finish in various industries due to its durability and aesthetic appeal. However, achieving a perfect finish on stainless steel can be a challenging process that requires the expertise of highly skilled professionals. At Dealercast, we have a team of experts who specialise in various polishing techniques that can produce the desired level of shine and finish.

At Dealercast, we use state-of-the-art equipment and highly skilled professionals to produce flawless polished stainless steel finishes. Our team has years of experience in achieving outstanding results, ensuring that your project is of the highest quality, regardless of size or complexity.

We offer a range of polished stainless steel finishes, including satin, bright, mirror, brushed, electropolishing, electrolytic polishing, and passivation. Each finish has unique characteristics and is suitable for specific applications, making it essential to understand each finish’s benefits.

Benefits of Stainless Steel Polishing

-

Enhanced Corrosion Resistance

Stainless steel is already known for its corrosion-resistant properties, thanks to its high chromium content. However, polishing the surface further improves its ability to resist rust, stains, and other forms of corrosion. The smooth and reflective surface created through polishing helps create a protective barrier against environmental elements and corrosive substances.

-

Improved Aesthetics

Polishing stainless steel enhances its visual appeal by creating a sleek and reflective surface. The smoothness and shine of polished stainless steel make it an excellent choice for applications where aesthetics are important, such as architectural designs, automotive parts, household appliances, and decorative items. The reflective nature of polished stainless steel can also contribute to a brighter and more spacious appearance in various settings.

-

Increased Durability

Polishing stainless steel not only enhances its resistance to corrosion but also improves its overall durability. The process removes surface imperfections, such as scratches, rough spots, and blemishes, making the material more resistant to wear and tear. Polished stainless steel is less likely to accumulate dirt, grime, or contaminants, allowing for easier cleaning and maintenance.

Our Range of Polishing

Brushed Finish

Brushed finish is achieved by using a wire brush or abrasive material to create a textured, matte surface. It is ideal for applications where a textured, non-reflective surface is desired, such as in kitchen appliances and industrial equipment.

Bright Finish

Bright finish is a highly reflective finish that is achieved by using a polishing compound and cloth mops. It is ideal for applications where a shiny, reflective surface is desired, such as in automotive and aerospace industries. Imperfections are not removed, so some small scratches can still be seen.

Mirror Finish

Mirror finish is the most reflective finish available and is achieved by using a series of abrasive materials to create a flawless, mirror-like surface. It is ideal for applications where a highly reflective surface is desired, such as in medical and scientific equipment. All imperfections including small scratches are completely removed to leave a flawless finish.

Metal Polishing Processes

- Brushed Finish

- Bright Finish

- Mirror Finish

The brushed finish is achieved through a process of abrasive polishing, which creates a smooth, uniform surface with a soft, matte appearance. This elegant finish is perfect for applications where a subtle, sophisticated look is desired, such as in architectural and interior design projects. The brushed finish is best suited for indoor environments and moderate climates, as it offers a balance of corrosion resistance and visual appeal.

Process:

The brushed finish is produced by using a combination of abrasive materials, including sandpaper, wire brushes, and other specialised tools. This process creates a soft and even finish that is perfect for applications where a low sheen is desired.

Working with abrasive pads or sandpaper (grits: 180, 320, 400, and 600), the surface is scratched along the direction of the steels grain using the most course grit to remove initial deep surface defects. This process continues until the desired finish is achieved.

Benefits:

Brush finish stainless steel is an excellent choice for applications where durability and corrosion resistance are required. It is easy to clean and maintain, making it ideal for use in areas that require frequent cleaning, such as commercial kitchens and hospitals. The brush finish hides fingerprints and scratches well, making it a popular choice for high-traffic areas.

Where to use:

Brush finish stainless steel is commonly used in a variety of applications, including architecture, automotive, and consumer goods. It is an ideal choice for decorative applications, such as furniture, fixtures, and appliances. Satin finish stainless steel is also used in industrial applications where durability and corrosion resistance are required, such as in food processing equipment, pharmaceuticals, and chemical plants.

Environment:

Brush finish stainless steel is suitable for use in a variety of environments. Additionally, the satin finish is less reflective than other finishes, making it a great choice for applications in bright or highly-lit environments where glare can be a problem.

A bright finish is created by using a series of polishing and buffing processes, resulting in a highly reflective, mirror-like surface. This dazzling finish is ideal for applications where a striking, eye-catching appearance is desired, such as in retail displays, automotive trim, and decorative elements. The bright finish is suitable for both indoor and outdoor environments, as it provides excellent corrosion resistance and can withstand a wide range of climates.

It is often used in applications where a high level of shine is desired, but the mirror finish is not required. The bright polish and mirror polish differ as with the bright polish, any surface defects are not removed. Likely, there will still be some scratches in the surface.

Process:

To achieve a bright polished finish on stainless steel, a soft cloth and polishing compound are used to achieve a high level of shine.

Benefits:

A bright polished finish provides a high level of shine and a smooth, even surface. It is highly resistant to corrosion and staining and is easy to clean and maintain.

Where to use:

Bright polished stainless steel is versatile and can be used in a variety of applications, from industrial to decorative. It is commonly used in environments where hygiene is important, such as in the food and pharmaceutical industries. It is also popular for architectural and interior design applications where a luxurious, high-end appearance is desired.

This finish is ideal for a variety of applications, including:

- Food processing equipment

- Pharmaceutical equipment

- Architectural features such as handrails, balustrades, and elevator interiors

- Automotive parts such as exhaust systems, wheels, and trim

- Marine components such as boat fittings and fixtures

Environment:

Bright polished stainless steel is suitable for use in a variety of environments, but it is particularly useful in applications where a high level of shine is desired. This finish provides a brilliant, mirror-like appearance that is ideal for decorative applications and luxury products. It is also highly resistant to corrosion and staining, making it a great choice for use in marine and coastal environments.

The mirror finish is achieved through a meticulous polishing process that creates a flawless, highly reflective surface. This impeccable finish is perfect for applications where a pristine, luxurious appearance is desired, such as in high-end architectural projects, luxury vehicles, and premium kitchen appliances. The mirror finish is best suited for indoor environments and controlled climates, as it offers superior corrosion resistance and a stunning visual impact.

Mirror finish is a highly polished finish that produces a reflective surface that is almost like a mirror. It is achieved through a multi-stage polishing process that involves using increasingly finer abrasive materials, much like brush polishing and bright polishing used together as one long process. Mirror finishes are often used in applications where appearance is important, such as in architectural features, automotive parts, and marine components.

Process:

To achieve a mirror polish on stainless steel, the surface is first prepared by grinding or sanding to remove any scratches, dents, or imperfections. The surface is then polished using a series of abrasive materials, starting with coarse abrasives and progressing to increasingly finer abrasives until there are no surface defects. After each stage of polishing, the surface is thoroughly cleaned to remove any abrasive residue. The final stage of polishing involves bright polishing using a soft cloth and a polishing compound to achieve a high level of reflectivity.

Benefits:

Mirror polishing creates a highly reflective surface that resembles a mirror. It provides a smooth and even surface, which is resistant to corrosion and staining. This finish is easy to clean and maintain. The key benefits include:

- Highly reflective surface that provides the highest level of shine and reflectivity.

- Smooth and even surface appearance.

- Resistant to corrosion and staining.

- Easy to clean and maintain.

Best Used:

Mirror polished stainless steel is particularly suited for applications where a high level of shine and reflectivity is desired. It is commonly used in:

- Architectural features such as handrails, balustrades, and elevator interiors.

- Automotive parts such as exhaust systems, wheels, and trim.

- Marine components such as boat fittings and fixtures.

Environment:

Mirror polishing is best suited for use in dry environments. It is often preferred for applications near oceans due to its high resistance to corrosion. The mirror finish provides a brilliant and reflective surface, adding a touch of elegance and sophistication to various settings.